Architecture analysis and

Success Story in collaboration with TR-Electronic GmbH

Architecture analysis and MISRA checking for automation technology firmware

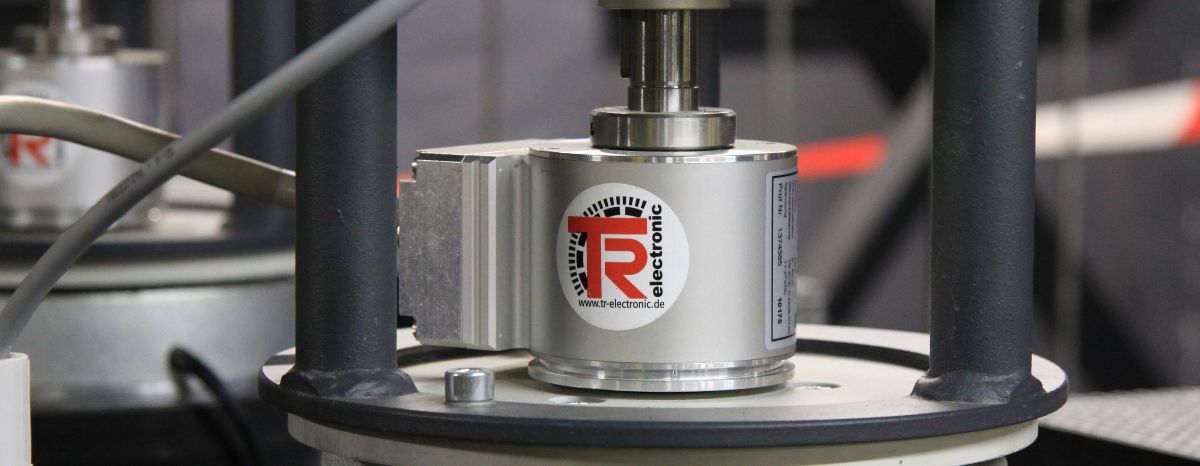

TR-Electronic in Trossingen specialises in sensors and actuators for industrial applications in automation technology. Its product portfolio includes rotary encoders, linear encoders, intelligent compact drives, as well as control and measuring modules. The firmware for its automation solutions relies on architecture models that simultaneously provide the foundation for further and new developments within the company’s various Business Units. Now, TR-Electronic is about to ensure that custom requirements are implemented consistently and that demanding security standards are met by introducing a new static code analysis function as part of the Axivion Suite.

THE CHALLENGE ++

TR-Electronic’s measuring and control solutions are employed in many fields, from metal and wood processing to the print and packaging industry, as well as event engineering and wind turbines. The firmware for the company’s high-quality standard products and for its custom solutions meets the requirements for a carefully modelled architecture. In this way, the company ensures that the different firmware variants remain manageable and that secure further development is possible in the long term.

The only way to ensure strict compliance with the models created by the software architects is to adopt a consistent, tool-based approach to architecture analysis. The software tool used for this purpose had to be seamlessly integrated into the development process. As well as checking that the code conforms to the existing architecture models for the firmware, the tool needed to provide feedback on the design so that the architects could use this to further optimise their models.

An additional requirement for the analysis tool concerned safety and security analyses: TR-Electronic’s sensors and actuators are increasingly being deployed in Industry 4.0 applications and for monitoring crucial safety-related machine functions. In these areas, technical safety standards are becoming ever stricter in an effort to protect networked production units from malicious software and unauthorised access. A tool was therefore needed that could also perform analyses to prevent systematic safety and security errors, including automated checks to ensure compliance with relevant programming guidelines such as CERT®. The new suite of tools was also intended to replace, as seamlessly as possible, the previous static code analysis tool that was being used to check compliance with MISRA C:2012 coding guidelines.

THE SOLUTION ++

The Axivion Suite fitted the bill exactly thanks to its precise analyses and straightforward integration into the existing TR-Electronic toolchain and development workflows. Migrating from the existing static code analysis tool to the Axivion Suite was a quick and smooth process, as was the process of customisation by Axivion’s Professional Services Team.

The tool suite will be used to analyse the code developed using C programming language. The integrated MISRA checker will cover all the MISRA rules from programming standard MISRA C:2012 that can be automatically checked, as well as the CERT® programming rules that are crucial for software security. As part of the architecture verification, the existing Enterprise Architect UML models will be automatically imported and their code checked for compliance. The Axivion Suite will fit seamlessly into TR-Electronic’s nightly build toolchain.

THE SUCCESS ++

TR-Electronic already had test tools in place for automated checking of the external firmware quality, such as functional suitability, efficiency etc. With the introduction of the Axivion Suite, it now also possesses an efficient tool for automatically checking the internal quality of its software as well.

The tool suite will be responsible for automated checking of the firmware code and architecture after every single build. The analyses reliably check for compliance with the metric threshold values, as well as company-specific and general programming rules such as MISRA and CERT®, and indicate any violations of the defined software architecture. The architecture verification ensures that interface requirements are consistently upheld, thereby supporting encapsulation into modules.

The short feedback cycles, particularly in the case of architecture violations during ongoing code development, soon had a positive impact on the programming quality. Not least because the regular and meaningful feedback enables prompt corrections to coding, but also because it facilitated rapid learning for the developers.

Overall, TR-Electronic has significantly reduced the level of human effort required in verifying and validating software architectures and codes. At the same time, the Axivion Suite rounds off the development team’s existing toolchain by ensuring security within firmware development.

ABOUT TR-ELECTRONIC ++

TR-Electronic develops, manufactures and sells sensors and actuators for industrial applications in automation technology. Products in the Rotary Encoders Business Unit with optical or magnetic scanning are required to detect the angular movement of a rotating shaft. Magnetostrictive linear encoders measure the position of a linear movement without contact, for example in a hydraulic cylinder. Intelligent compact drives from the Motion Business Unit are used as actuators or process drives. Customized control and measuring modules in combination with special know-how in pressing and punching processes complete the product portfolio. The Components Business Unit supplies automation components. The development services provided by the Automation Business Unit bring press lines to new levels of performance and enable with smart metering solutions an efficient energy utilization, the remote monitoring of water supply networks or intelligent heating automation.

TR-Electronic’s most important customer is the mechanical and plant engineering industry, which has a strong tradition in Germany. In addition to the primary location of Trossingen, subsidiaries and technical sales partners in Europe, the USA, Canada, Brazil and Asia offer professional advice and project planning and ensure worldwide access to the TR product range.

More information about TR-Electronic at www.tr-electronic.de

Image rights: TR-Electronic GmbH, Trossingen