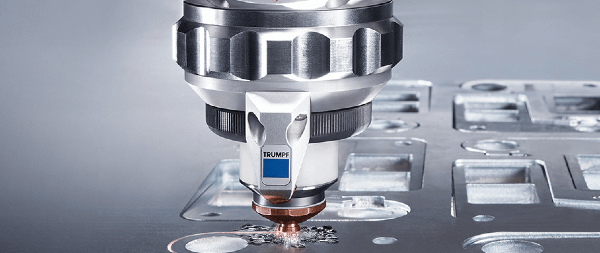

Success Story in collaboration with TRUMPF Laser

TRUMPF Laser, in Schramberg, guarantees the quality of its software by using Axivion Suite code and architecture verification

TRUMPF is a technology and market leader when it comes to machine tools for flexible sheet metal processing and industrial lasers. When developing the software for the laser systems at its Schramberg site, TRUMPF Laser uses Axivion Suite.

THE CHALLENGE ++

At TRUMPF’s Schramberg location, Axivion’s task is to protect the software developed both for embedded and PC software from software erosion. The code, on which the various systems are based, has been continuously refined over a period of years and in ever shorter innovation cycles – for greater functionality and a wider product range. During this process, the overall complexity of the software and its variants has also increased. Keeping all of this manageable represents a continuous challenge for developers.

This is coupled with increasing quality requirements in the industrial sector, which have to be met – right down to code level. Manual reviews cannot be used to guarantee compliance with self-imposed and industry-wide coding/quality standards in an economical and efficient way. Therefore, the aim is to automate the code and architecture verification process as far as possible.

Another reason why this is so important is that the software development teams at TRUMPF Laser in Schramberg are growing ever larger. Software plays a key role in the high level of innovation built into TRUMPF products. However, having a growing workforce does create additional challenges. With an ever-increasing number of programmers, including new colleagues, working together on a common code base and adding a steady stream of new program sections to the software, the challenge is to ensure that the joint coding standards are maintained at all times and, above all, the software architecture is understood and rigorously implemented.

THE SOLUTION ++

At Schramberg, TRUMPF Laser has relied on Axivion Suite for quite some time. TRUMPF’s developers use the tool suite and its automated analysis and reporting features in their regular reviews of both new software components and, via delta analysis, the existing software.

The Axivion Suite seeks out style violations and metric violations in the programming in a targeted way, while also localizing clones and dead code. The affected code locations are marked, and displayed for developers for further systematic processing, both directly in the IDE and through transparent reporting processes.

The Axivion Suite also offers active support with the ongoing creation of product-specific software architecture. Rigorous compliance with this architecture during all stages of software development is guaranteed by the tool suite’s automated architecture verification process. This immediately flags up any failure to meet specifications correctly. In this way, developers are not only able to correct possible violations immediately, but can also benefit from a personal learning effect in terms of correct implementation of the specified software architecture.

The technical integration of Axivion Suite at TRUMPF Laser in Schramberg is conducted by experts from Axivion’s professional services team. As part of this process, they not only install the tool suite and its plugins directly into the developer’s workstation, but also add such things as TRUMPF-specific metrics and coding guidelines to the code and architecture verification tools.

The development teams are provided with personal training, which enables them to incorporate the Axivion Suite into their daily working practices without any great delay.

THE SUCCESS ++

The success of Axivion Suite at TRUMPF Laser is reflected by its increased developer productivity. Automating the code and architecture verification process, which used to be a time-consuming manual task, has permanently reduced the employees’ work load. Another reason for using the tool suite is that it also displays potentially problematic coding, which could never be detected by manual means. For example, the “cycle detection” function homes in on cyclical dependencies across several components in a precisely targeted fashion.

Thanks to its direct analysis, the Axivion Suite also improves developers’ understanding of the architecture models. Swift feedback means that the architecture is clear and easy for individual users to understand, and can be implemented correctly and immediately, with increasing frequency, thanks to the automatic learning process. Moreover, the architecture documentation can be much more precisely formulated and kept up to date without any great effort.

All this greatly benefits new members of the development team: the Axivion Suite’s clear, easy to understand rules and transparent documentation ensure that software developers quickly become familiar with the system. Thanks to the regular automated feedback from the tools, they pick up and internalize the coding standards and architecture models in no time at all, so that they can be relied upon to integrate them into their programming work.

Reducing workload for the TRUMPF development team at Schramberg via the automated code and architecture analysis process frees up capacity and thus allows the personnel to focus once again on the content of their software implementations. The time saved in this way also allows the software architects to concentrate more on conceptual software planning.

All in all, the software developers at TRUMPF Laser regard the Axivion Suite as an additional “safety net”. The regular analyses and reports make the growing code quality visible, which boosts the team’s confidence in its own development work. For TRUMPF Laser, this guarantees long-term development success in an environment marked by high performance and quality requirements over ever shorter innovation and product cycles.

ABOUT TRUMPF ++

The high-technology company TRUMPF offers production solutions in the machine tool and laser sectors. It is driving digital connectivity in manufacturing industry through consulting, platform and software offers. TRUMPF is the world technological and market leader for machine tools used in flexible sheet metal processing, and also for industrial lasers.

In 2016/17, the TRUMPF Group – which has about 12,000 employees – achieved sales of 3.11 billion euros. With over 70 subsidiaries, it is represented in nearly all the countries of Europe, North and South America, and Asia. It has production facilities in Germany, France, Great Britain, Italy, Austria, Switzerland, Poland, the Czech Republic, the USA, Mexico, China and Japan.

For more information about TRUMPF go to www.trumpf.com

Image rights: TRUMPF Laser